Access a network of 70+ sawmills with one point of contact

Effortless timber sourcing with one reliable partner ensures predictable planning for you.

We partner with big sawmills & small to medium specialised suppliers to cover all types of products.

DACH

Number of sawmills

25

Quality

Tegernseer Customs

Type of products

Packaging beams, fresh/KD

Packaging sideboards, fresh/KD

KVH/glulam

Nordics

Number of sawmills

20

Quality

Schaalboards, sexta (packaging)

Sexta, SF, U/S (construction)

Type of products

Packaging/Construction timber, redwood/whitewood (pine/spruce), KD

Planed timber

Baltics

Number of sawmills

10

Quality

Grade 1, Grade 2 (CTL)

Upon customer specification (LL)

Type of products

Packaging timber, CTL, fresh softwood/mixed hardwood

Packaging timber, CTL, KD, softwood

Construction timber, LL, fresh/KD

Balkans

Number of sawmills

12

Quality

Grade 1, Grade 2 (CTL)

Upon customer specification (LL)

Type of products

Packaging timber, CTL, fresh softwood/mixed hardwood

Construction timber, LL, fresh/KD

Central Europe & Ukraine

Number of sawmills

5

Quality

Grade 1, Grade 2 (CTL)

Upon customer specification (LL)

Type of products

Pallet timber, CTL, KD

Packaging timber, LL, KD

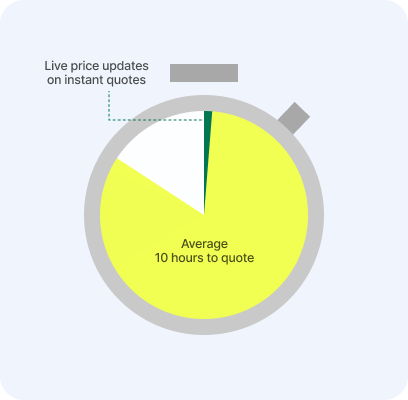

From first request to delivery, our network speeds up the ordering process like never before.

Fast delivery, starting from

1 week

Average time to quote

10 hours

Average time to solve a claim

24 hours

Our vetting process

Building strong relationships with our suppliers is at the heart of our quality control

1

First in person visit

Our experts first visit each sawmill in person to inspect the production processes, machinery, identify potential product opportunities.

2

Trial loads

We quality-check each new sawmill partner by monitoring trial loads to customers or directly at their facilities, ensuring smooth service and high standards.

3

Regular on-site visits & in-person product development

We regularly visit all partners to explore new products, inspect facilities, and collaboratively enhance supplier process efficiency for our buyers.

4

Focus on existing partnerships

Our current focus is on maximising the value of each existing partnership through regular visits, improving ways of working rather than continually expanding our network of sawmills.

I started using Timberhub post-COVID to diversify my supply network and have been very happy with their quality and simplicity.

Owner - Sirch

29 trucks ordered

Got a question?

While the majority of our suppliers are based in Europe, we are in the process of expanding our network to include e.g. some producers in Africa. On site, we are also adapting our vetting process to suit the region.If you are interested in timber outside of Europe, please just request a quote or get in touch with us directly.